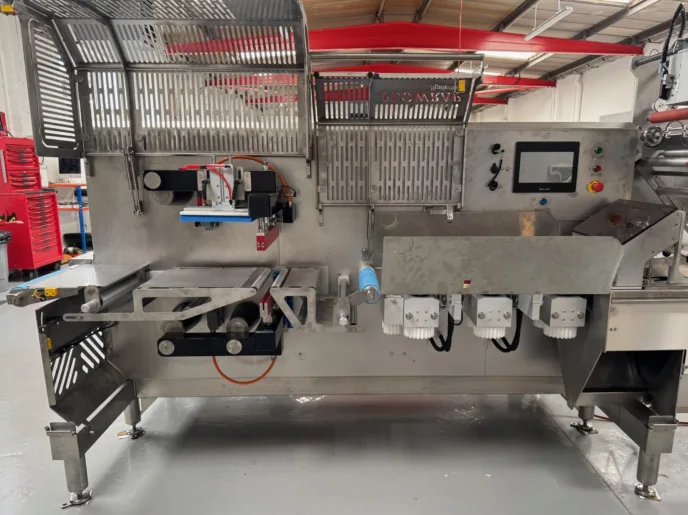

The Summit Long Dwell Flowrapper

The Summit machine from Flowrap Systems sets a new standard in the world of horizontal form, fill and seal (HFFS) machinery.

Great seal integrity, excellent hygiene and very low-maintenance, the Summit is built unlike any other machine.

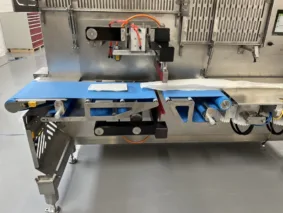

Fully stripped down in less than a minute - NO TOOLS, NO LOOSE FIXINGS

These images show our competitor's standards. Belt removal is difficult and requires many tools.

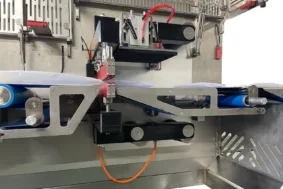

Base (fin) seal system

The base seal has system is unique in that it does not use heated wheels. This offers the following benefits:

Dwell time

Heated wheels have only a very brief period in which to heat and seal the film. The SUMMIT machine provides a much longer dwell time for the film to be heated, allowing for to reduced sealing temperatures whilst maintaining results. On a side-by-side comparison, we were able to run at a temperature of 125°C, compared with 170°C on a traditional wheel system.

Bearing life

Because we are not using HOT wheels, we do not suffer from early failure of bearings from over-heating.

NO rotating electrical couplings

With only cold wheels, we remove the requirement for slip-rings or other rotating electrical couplings.

Redundancy built-in

The heater circuits have twin heater elements which ensure that a sudden failure does not stop production.

Jaw seal system

The jaw system has been designed to be the most hygienic and easy to maintain on the market. The benefits are:

- All drive components live within the machine body, away from the product area.

- The pre-jaw and discharge belts are quick release and tool-less changover. Belts can be removed and re-fitted in less than a minute

- Redundancy built-in. As with the back seal, the jaws have twin heater elements on each circuit.

- No hidden ledges. Any debris which falls from the product as it is packed is easily identified and cleaned. There are no hidden voids where old product can accumulate.

- Tool-free knife removal and refitting.

- One-bolt jaw head removal for off-line maintenance.

- Fully-enclosed spring mechanism for long-life and improved hygiene.

Film tension and User interface

Film tension

Film tension is accurately controlled using a driven mandrel with encoder feedback. No load-cells are required. This gives exact film tension control, which is a growing requirement for the new recyclable materials.

The whole film path is mounted on a common frame. This means that when making adjustments to the film tracking, no further adjustments are needed for the printer and registration-mark sensor.

User interface

The machine HMI and the date-code printer screen are both integrated into the machine body. Their side-by-side positioning eliminates ugly external wiring looms and is more ergonomic for the operators.

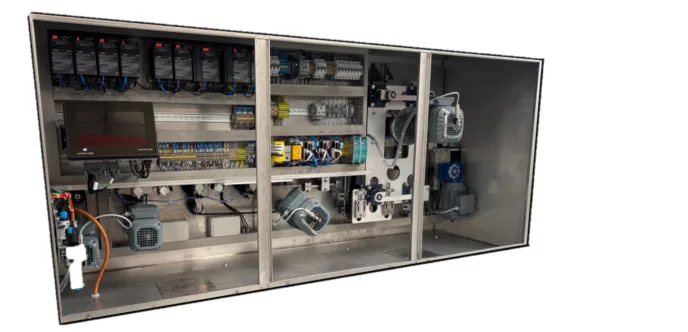

Main mechanical and electrical systems

Mechanical simplicity

- No lubrication requirement.

- All drives via HTD timing belt – no tensioning requirement.

- Can be supplied with AC motors or Servo motors, to customer preference.

Electrical system

- Allen Bradley or Mitsubiushi control platform.

- All components are commercially available - NO proprietary electronics.

- Full diagnostics via the HMI pages.

- Remote access link for urgent service support built in as standard (license fee applies)

- Remote monitor and backup, subject to service contract.

Gallery

Summit Specifications

| Specification | Value |

|---|---|

|

Width of product |

Up to 330 mm (Up to 13”) |

|

Maximum height of product |

Up to 100 mm (Up to 4") |

|

Maximum film reel diameter |

350 mm |

|

Maximum film reel width |

700 mm |

|

Maximum speed (packs per minute, product and film dependent) |

100 ppm |

|

No product-no bag function |

Yes |

|

Misplaced product function |

Yes |

|

Number of film reel holders |

1 as standard; option for twin reel with auto-splice |

|

Folding boxes |

Adjustable folding box, size range 75 – 210mm wide |

Downloads

Summit Datasheet

Enquire

Have questions about the HFFS machine? Want to talk to an expert? Fill out this form and we'll be in touch ASAP.